It was founded in the garage of a suburban New Jersey split-level, with only $435 worth of equipment and a dream to prove the establishment wrong. No, this isn’t the origin story of a garage band that made it big, this is the story of how S4J Manufacturing Services got its start.

S4J Manufacturing founder Steven Gyure was a regular jack-of-all-trades in the manufacturing industry, having worked in a variety of positions since his youth and acquiring a plethora of skills. His final stop before striking out on his own was at an architectural supply company, where he quickly took on a leading role as a product designer. He knew he was bringing in a lot of revenue, but he wasn’t seeing that reflected in his paycheck. While he had no qualms about demanding a raise from the notoriously frugal and cantankerous boss, he knew his co-workers might not be so brave. Steve wasn’t a fan of that kind of treatment of employees, but he also didn’t believe that he had the right to tell someone how to run their business. So he started his own, because he wanted to prove that he could make a respectable living and still be a decent boss.

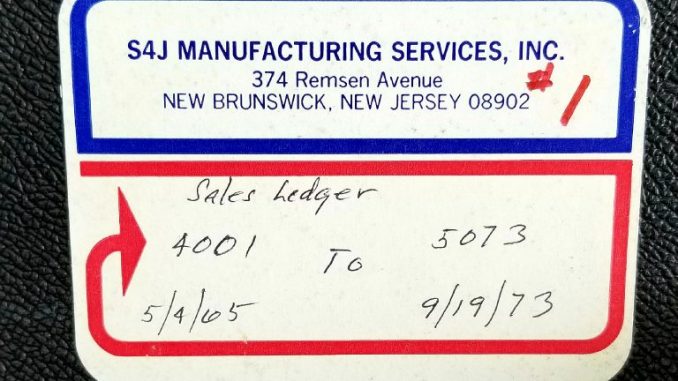

He started off small in 1965, with a part-time business running out of his garage, still working for the architectural supply company. The only heavy machinery he had was a drill press with a tapping attachment, and his first big job was an order for 1.4 million aluminum tubings with holes punched in them. By 1968 he felt he was ready to go big or go home and make his manufacturing business a full-time venture… that is of course if he had a home to which he could go back. In those early years he was made well aware, whether it was by his boss at the architectural supply company or local business associations, that it was likely S4J Manufacturing wouldn’t survive and that he could put himself and his young family in economic jeopardy.

For modern-day entrepreneurs, the statistics for business success haven’t gotten any less daunting. Latest Bureau of Labor Statistics numbers show that 20% of small business fail in their 1st year, while only 30% of small businesses survive their 10th year. Risk-taking is part and parcel with life as a business owner, something that Steve knew all too well in the first decade and a half of S4J’s life.

After he made S4J his full-time job he provided an expansive range of products, making anything from the smallest medical connectors to big construction elevators, in his small factory. He was willing to do any job within reason to keep his business afloat. When the recession of the late 70’s hit though, he realized that his business model needed to change if he really wanted to make it past the 10 year mark and prove the naysayers wrong.

That epiphany-esque moment came when a catheter company to which S4J supplied Luer-lok fittings told him that if S4J focused on selling those parts, he would get a lot of business from other medical instrument companies. Now if you haven’t figured it out already, Steve Gyure is a stubborn man, known even amongst his children and grandchildren as a man who rarely takes advice on what to do with his life. However he knew this was a make or break moment, so he took the risk, listened to the advice, and in 1980 S4J started its own line of Luer fittings and made that its main area of production. By 1983 sales from medical companies were able to support S4J Manufacturing.

Over 50 years later S4J Manufacturing is still here, the product of true entrepreneurial grit and ingenuity. More risk-taking and adaptation has certainly occurred to get us to this point, but those are stories for another time.

Leave a Reply